When the blade dryer is used for a long time, the blade dryer will appear the phenomenon of corrosion, then, what is the cause of this phenomenon?

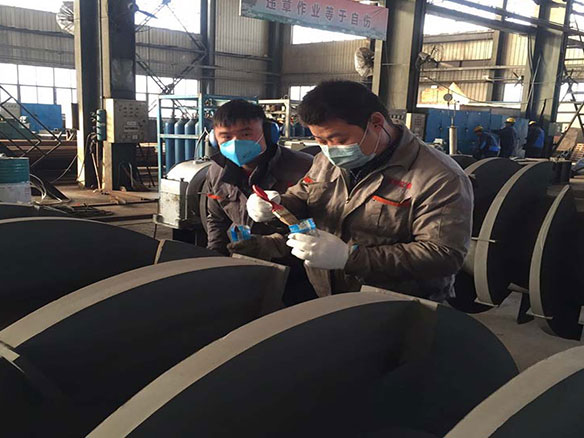

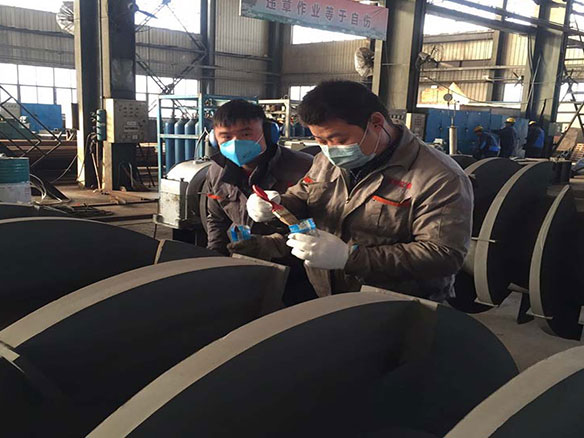

Our company has successfully applied wet-resistant, corrosion-resistant and high-temperature tungsten carbide coating to the blade shaft, blade and tank of sludge dryer made by Mitsubishi Heavy Industries in Japan through supersonic spraying, which has greatly improved the service life of the parts after continuous use and tracking by customers.