As the most popular plasma spray gun, our company provides the imitation METCO 9M spray gun. The main gas of the spray gun is argon or nitrogen, and the auxiliary gas is hydrogen.

As the most popular plasma spray gun, our company provides the imitation METCO 9M spray gun. The main gas of the spray gun is argon or nitrogen, and the auxiliary gas is hydrogen. The spray gun provides the following accessories: nozzle, powder feeding tube and powder feeding rack, water cable, electrode head, insulator, sealing ring, special tools, etc. The spray gun is used in manufacturing type thermal spraying operation and can work continuously for a long time. The spray gun is widely used in the world and has been proved to be the most stable and reliable universal plasma spray gun. The spray gun has hundreds of customers in China and has been used in the thermal spraying industry maturely.

Working current: 100-800A, working voltage: Ar+H2:30-85V, N2+H2:37-80V. This type of spray gun is used for manufacturing type thermal spraying. Its maximum output power is up to 45KW. Plasma spraying is carried out by using plasma arc, ion arc is compression arc, compared with free arc, its arc column is thin, current density is large, gas ionization degree is high, so it has high temperature, energy concentration, arc stability and other characteristics.

The spray gun adopts non-transfer arc: refers to the plasma arc generated between the cathode and the nozzle. The positive electrode is connected to the nozzle, the workpiece is not charged, between the cathode and the inner wall of the nozzle to produce an arc, the working gas is heated through the arc between the cathode and the nozzle, causing all or part of the ionization, and then ejected from the nozzle to form a plasma flame (or plasma jet).

The 9MB spray gun's external powder feed design enables it to deliver powder under low pressure, unlike some spray guns which require a high pressure powder feed, thus improving the process stability.

| No. | Name | Characteristics | The project content parameter | Note |

| 1 | LP - 9 MB spray gun | The main gas of the METCO 9M lance is argon or nitrogen, and the auxiliary gas is hydrogen. The spray gun provides the following accessories: nozzle, powder feeding tube and powder feeding rack, water cable, electrode head, insulator, sealing ring, special tools, etc. The spray gun is used for manufacturing type thermal spraying and can work continuously for a long time. |

1. Operating current: 100 ~ 800A 2. Operating voltage: Ar+H2 is 30 ~ 85V, N2+H2 is 37 ~ 80V. 3. The maximum output power reaches 45KW. |

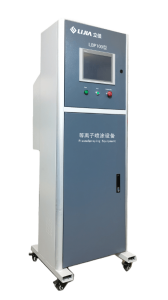

The LBP-100 control cabinet is a truly closed-loop control system in which all process gases and powder carriers are digitally managed through an advanced mass flow meter to ensure high accuracy and repeatability of the spraying process. This system adopts PLC control system operation, the operator can easily input related process parameters or call the previous spraying formula through the graphical man-machine interface, the system can record and monitor the whole process of spraying in real time.

LBP-100 control cabinet is the control center of all spraying process. Built-in high-end PLC and various software, responsible for the completion of all the control process. All important process parameters are closed-loop controlled to ensure process stability and repeatability. The touch screen is used as man-machine interface to input spraying process parameters and display spraying status. The operation of the system is real-time monitoring.

The system can store all engineering parameters and can be called directly when used. Through the main operation interface of the touch screen, users can easily store, call and modify the spraying parameters.

Man-machine interface adopts 12-inch large-size touch screen, on which each component of the whole set of equipment (such as gas control area, power supply and powder feeding control area, etc.) is displayed graphically to make the operator clear at a glance. The man-machine interface is used to input spraying parameters, store spraying parameters and display spraying status. When the system gives an error alarm, the relevant error information will also be displayed on the human-machine interface.

On the touch screen, the user can set all the process parameters and make all the spraying parameters visible. For different types of spray guns, the built-in PLC of the system presets parameters such as ignition, parameter climb and power limit, etc., so as to avoid the burning of parts of the spray gun due to the wrong parameter setting.

The LBP-100 control cabinet also has a self-diagnosing function to monitor equipment flow, pressure and sensor operation status. Once an alarm occurs, the system will automatically stop the gun, and the touch screen interface will alarm. The operator can know the source of the alarm by viewing the alarm page, so as to know the cause of the fault. All alarms automatically keep historical records such as trigger reason, time, date, etc., which helps operators to understand the condition of the equipment.

LBP-100 control cabinet can monitor all peripheral equipment. When peripheral equipment, precipitator and chiller are not started, ignition is not allowed in the system to ensure the safety of spray gun and spraying room. When manipulator, precipitator and chiller fail, the spray gun will be stopped immediately.

LBP-100 system has standby function, that is, if the spraying operation needs to be stopped for a short time during the spraying process for some reason, the equipment can be put into standby state by pressing the "Run" button. In standby mode, the spray gun is still firing, but all the utilities are at the minimum consumption required to maintain ignition. Once the normal spraying work needs to be resumed, press the "run" button to remove the standby state, and the process parameters will return to the set value to enter the normal spraying state. The purpose of this function is to avoid the loss of nozzle and fuel caused by repeated shutdown during spraying operation.

The system can also monitor the running state of the host in real time and generate graph state automatically.

| No. | Name | Characteristics | The project content parameter | Note |

| 1 | LBP-10 plasma spraying control cabinet | The system adopts PLC and touch screen control, and the gas adopts mass flow control system. The user will adjust the required parameters well, and then confirm to start, and the system will automatically adjust the required parameters. During the spraying process, the system will collect the parameters in the spraying process in real time, analyze and judge the parameters, ensure the stability of spraying operation, and protect the power spray gun |

1. Input voltage: AC380/3P/50Hz±5% 2. Input power: 300W 3. Control type: PLC + touch screen + mass flow controller 4. Main gas type and pressure: Argon (0.35-0.7mpa) 5. Secondary gas type and pressure: Hydrogen (0.3-0.45mpa) |

| No. | Name | Characteristics | The project content parameter | Note |

| 1 | Plasma inverter power supply | Plasma spraying main power supply is a new type of constant-current mode power supply. It is controlled by 80KW inverter and communicated by optical fiber and PLC to greatly improve the stability of the power supply. It controls the voltage fluctuation of the power supply plus or minus 1V and the current plus or minus 1A. Liquid crystal display and digital operation; And can realize the corresponding protection of the lighter count, and can realize the reasonable and fast arc extinguishing function on the basis of fully satisfying the power supply work; With a perfect data acquisition system, the power supply voltage, current, cooling temperature, conductivity, pressure, power and other real-time monitoring, data feedback analysis in a timely manner, in a timely manner to burn the gun protection. |

|

| No. | Component | Item | Parameter | Note | |||||

| 1 | C-1100 Powder feeder |

Compared with the traditional double barrel type powder feeder, the metering disc type powder feeder is more fine and the powder particle size range is wider. Metering panel feeder is finer than traditional dual-barrel feeder and scope of powder particle size is wider. The internationally ultromodern inclined structure is adopted to facilitate cleaning powder by overturning the barrel to pour out powder using 3 seconds. |

|

||||||

| No. | Component | Item | Parameter | Note |

| 1 | transfer box index | Mix the water and electricity of the plasma equipment and send it to the spray gun. At the same time, it provides the high frequency pulse voltage needed when the spray gun starts arc and detects the return water temperature and cooling water pressure of the spray gun. It is light, flexible and convenient for dragging. Good arc starting performance reduces the instantaneous current impact of nozzle arc starting. |

|

| No. | Component | Item | Parameter | Note |

| 1 | Cooling water system | By cooling the spray gun with the chiller, the stable operation of the spray gun can be guaranteed for a long time to obtain the best coating. Provide more safety protection: compressor overheating protection, overcurrent protection, high and low pressure protection, overtemperature protection, flow protection, phase sequence/phase loss protection, exhaust overheating protection, anti-freeze protection. |

|