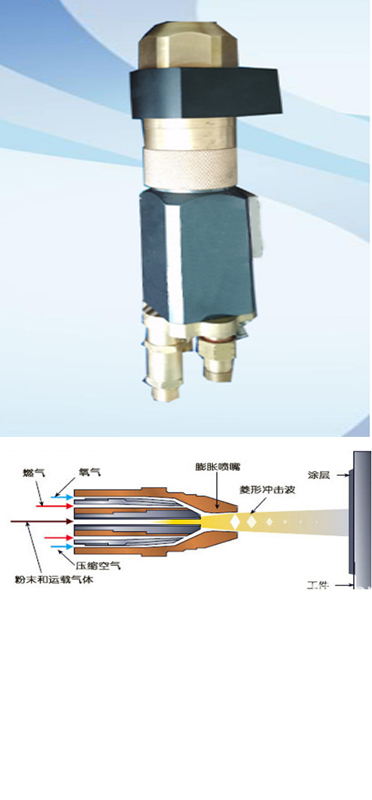

The main principle of THE LH-5000 supersonic flame spraying equipment: the mixture of gas and oxygen is sent to the ignition area at the exit of the spray gun at high pressure and ignites. The annular hot gas flow is compressed by the peripheral compressed air flow, which accelerates to form a supersonic flame. The powder is sent to the exit of the gun under the action of carrier gas and enters the burning flame to form a coating.

The main principle of THE LH-5000 supersonic flame spraying equipment: the mixture of gas and oxygen is sent to the ignition area at the exit of the spray gun at high pressure and ignites. The annular hot gas flow is compressed by the peripheral compressed air flow, which accelerates to form a supersonic flame. The powder is sent to the exit of the gun under the action of carrier gas and enters the burning flame to form a coating.

LH-5000 type supersonic flame spraying equipment is composed of spray gun, powder feeder, control system, heat exchange system and various pipelines. It is a compact spraying equipment with simple operation, stable operation, low fuel consumption and good coating performance.

LH-5000 supersonic flame spraying system has the advanced level of similar foreign products, superior performance, easy to operate. Can realize the automatic operation of the spraying process, and real-time monitoring of the system, dynamic control of the working process of the spray gun, can respond to the system failure immediately.

Parameters of the LH-5000 control cabinet

The LH-5000 supersonic and high speed flame spray powder feeder is used to store the powder and transfer the powder to the spray gun according to the process requirements. Nitrogen is used as powder air, and the powder is transported to the outlet of powder feeder by atomizing vibration of powder air, and the powder gas together with the powder gas leaves the powder bucket and enters the gun. The speed of powder feeding can be adjusted by adjusting the potentiometer on the panel of the control cabinet.

| 1 | Feeding way | Scraper air pressure type |

| 2 | Single barrel (double barrel) volume | Single 3.0 (double total 6.0) L |

| 3 | Send powder gas | Nitrogen or argon |

| 4 | Powder feed air pressure | 1.1-1.6MPa |

| 5 | Powder feeding speed | 0~160g/min |

| 6 | Feeding accuracy | ±1% |

| 7 | Flow rate of powder feeding gas | 400-800L/h |

| 8 | External dimensions of powder feeder | 500×460×1300mm |

| 9 | Weight of powder feeder | 130Kg |

Dual compressor drives reduce the overall volume and increase your space; Mainly used to make the nozzle, sealing ring to get effective cooling, to achieve the nozzle, sealing ring to prolong life.

| No | Item | Parameter | ||

| 1 | The unit shape | 1330×780×1310(mm) | ||

| 2 | Circulating tank capacity | 250KG | ||

| 3 | Refrigerating capacity | 35KW | ||

| 4 | Water outlet temperature fluctuation | 5℃ | ||

| 5 | The power supply | 3P AC380 50HZ/60HZ | ||

| 6 | The compressor | Double compressor | Origin: Daikin or Panasonic of Japan | |

| 7 | The water pressure | 4-8 kg is adjustable | Out of the water flow | 6 m3/h |

| 8 | The circulating pump | Rated power 1.1KW | Rated current1.5A | |

| 9 | Refrigerant injection capacity | 11Kg | Refrigeration coal | F22 |

| 10 | The fan power | 85W×2 | ||

| 11 | Total input power | 13.5KW | ||

| 12 | weight | 450Kg | ||

It is equipped with manual and machine-card two-purpose spray gun, and the working gas is oxygen and propane. The weight of spray gun is about 2Kg. Spray particle speed ≥450m/s. Spray gun can work stably for a long time.

| No | Item | Parameter |

| 1 | The flame speed | 2100m/s |

| 2 | Flame temperature | 2700℃ |

| 3 | Powder particle velocity | 500~650m/s |

| 4 | Cooling way | 水 冷 |

| 5 | Cooling water flow | 9.5L/min |

| 6 | Porosity of coating | <1% |

| 7 | Coating bonding strength | >70MPa |

| 8 | Spray powder size | 5-120μm |

| 9 | Pressure and flow of gas (propane) | 0.65MPa 88L/min |

| 10 | Oxygen pressure and flow | 1.1MPa 305L/min |

| 11 | Air pressure and flow | 0.75MPa 440L/min |

| 12 | Nitrogen pressure and flow | 1.2MPa 18 L/min |

| 13 | The hydrogen pressure | 0.35MPa |

| 14 | Airbrush dimensions | 420×230×50 |

| 15 | Spray gun weight | 2.8Kg |

| No. | Item | Model | Count | Unit | Price(USD) | Total prace(USD) |

| 1 | Control cabinet | LH-5000 | 1 | 套 | 9596.00 | 9596.00 |

| 2 | Powder feeder | LH-5000 | 1 | 套 | 5204.00 | 5204.00 |

| 3 | Spray gun | LH-5000 | 1 | 套 | 2928.00 | 2928.00 |

| 4 | Chiller system | LH-5000 | 1 | 套 | 4229.00 | 4229.00 |

| Total price | 21957.00 | |||||

The above quotation includes equipment only

All quotations and price information in this document are confidential and shall not be disclosed to any third party by the Client.

The programme has a period of 30 days

| No. | Item | Count | Price(USD) |

| 1 | Powder spraying pipe | 1 | 62.00 |

| 2 | The feeding tube | 1 | 59.00 |

| 3 | The nozzle | 1 | 91.00 |

| 4 | The internal casing | 1 | 36.00 |

| 5 | Rear powder feeding tube | 1 | 43.00 |