(1) Electrode size: ≤2200mmX2200mm

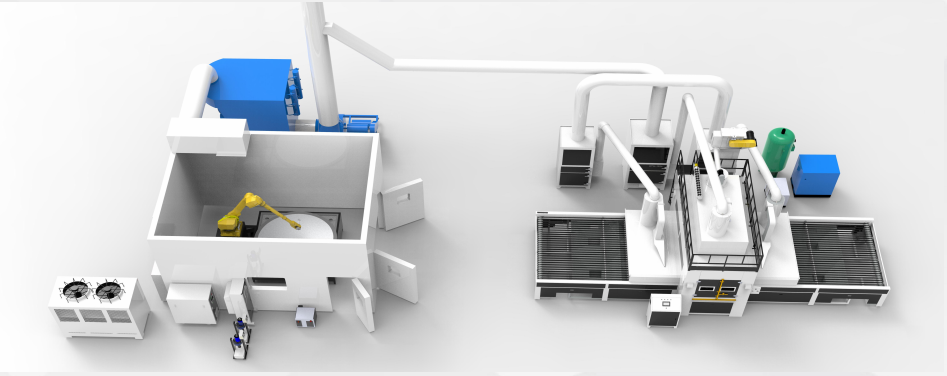

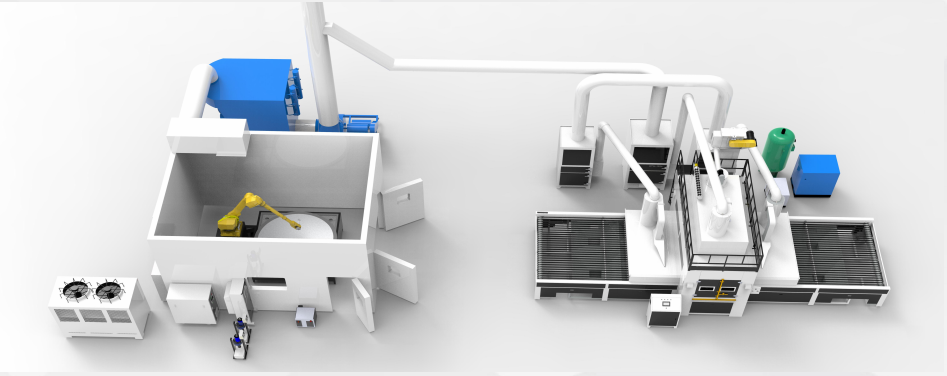

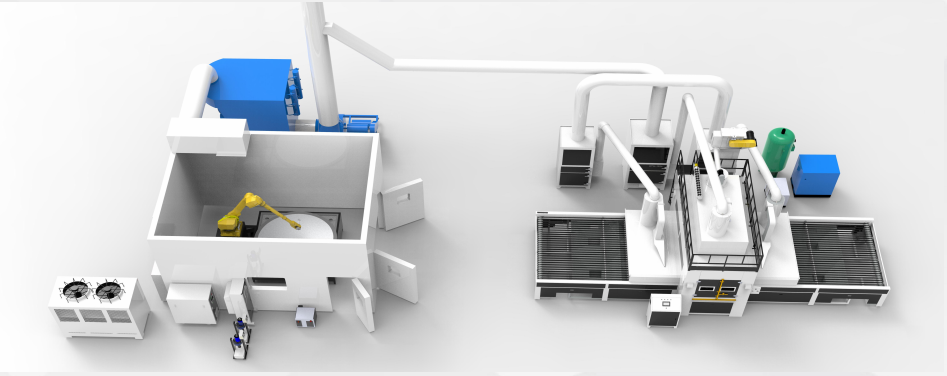

(2) Main configuration: 1 set of sandblasting +1 set of spraying

(3) Processing mode: automatic conveying sandblasting + simple spraying platform + manual entry into the room loading and unloading + six-axis universal manipulator automatic spraying (when loading and unloading need to stop the spray gun, the manipulator uses command programming mode to plan the spray path)

(4) Spraying time: Take 1855mm diameter nickel net as an example, spraying about 8-10 minutes to spray a piece.

(5) Manual loading and unloading time: it takes about 10 minutes to replace the workpiece in the spray room, and the spray gun should be stopped during the replacement to occupy the spraying time.

(6) Comprehensive beat: Take 1855mm diameter nickel net as an example, about 3 pieces per hour

(7) Coating materials: NiAl, NiMoAl, NiFeAl, NiXAl, NiXXAl (X is the third or fourth element) and other kinds of.

(8) Coating requirements: the nickel net after spraying, the weight of the nickel net after spraying is increased by 240g/ m2-300g/m2, the coating after spraying is firmly combined, the coating does not fall off when the nickel net is bent at 120°, the color of the nickel net after spraying is consistent, and the surface is flat.

① Adopt imported PLC full closed-loop control system, equipped with nickel mesh spray gun and compatible with mainstream spray gun

② Inlet mass flow control system

③INFINEON inverter power module, supporting full-function monitoring man-machine interface

④ Real-time display of residual powder and non-stop automatic switch powder feeder, continuous powder feeding to ensure continuous spraying

⑤ Spray gun up to 6 powder feeding mode, powder feeding uniform

⑥ Powder delivery speed up to 280g/min

⑦ Built-in storage 5000 spray formula process

⑧ Multiple login permissions to ensure process safety

⑨ Anti-freeze mode, the northern winter anti-freeze mode

⑩ Information center: continuous display of system status and alarm information