The d-3000 powder feeder is a high-precision with output from the measuring plate, which is suitable for the precise conveying of coating in thermal spraying equipment. Compared with screw, scraper and vibration conveying, it has higher accuracy and it saves powder.

The d-3000 powder feeder is a high-precision with output from the measuring plate, which is suitable for the precise conveying of coating in thermal spraying equipment. Compared with screw, scraper and vibration conveying, it has higher accuracy and it saves powder. The inner structure of the powder feeder is equipped with a unique blowing and self-cleaning structure, which can effectively conduct self-cleaning and prevent fine powder from being mixed in the parts of the equipment. It has a very significant effect on fine powder clogging. The coarse powder is more difficult to clog.

A low-flow nitrogen or argon gas is used as the powder feeding gas. The powder reaches the powder outlet with the rotation of the bottom powder feeding plate and enters the spray gun together with the powder feeding gas, which saves more gas than the traditional high-pressure powder feeding device.

The mass flow control system with full closed-loop control can automatically adjust the carrier gas flow, which has higher accuracy and stability than the traditional float flow-meter.

The measuring powder feeder is finer than the traditional double barrel feeder, and the range of powder particle size is wider.

At the same time, the powder feeder has the same appearance and structure principle as the Praxair 1264 powder feeder, which can make the mouth of the powder barrel turn upside down and complete the powder pouring and cleaning in three seconds. Now, it has been widely used in the thermal spraying equipment and has become one of the indispensable important devices in the thermal spraying industry.

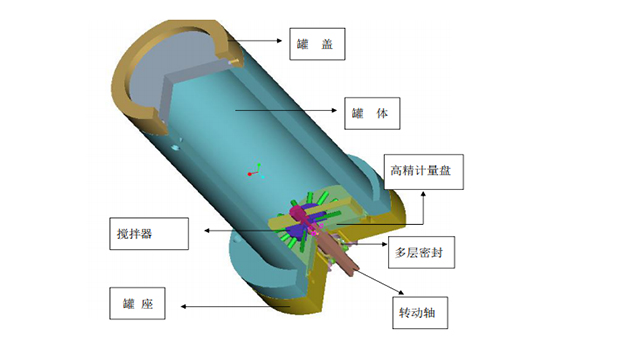

The D-3000 powder feeder is mainly composed of the main body of the powder feeder, the support and the mobile trolley.See Figure1. The main structure is composed of tank body, box body, electrical control, rotary drive and so on,See Figure2,The tank is composed of measuring plate, vibrating hammer, powder valve, gas carrier assembly, cylinder head and other parts.

Under the action of the agitator, the powder fills the hole of the measuring disc and hovered to the blanking port with the high-precision measurement driven by the infinitely variable speed motor rotating counterclockwise.Under the carrier gas pressure in the tank and the negative pressure generated by the powder feeding valve, the carrier gas is successively fed into the spray gun system to complete the thermal spraying.The spraying amount is controlled by a step less motor with 1-18 RPM. Accurate powder delivery can greatly improve the uniformity of coating and spraying quality.

| No | Component | Item | Parameter | Note |

| 1 | D-3000 Powder feeder |

1.The powder feeder is a high precision powder feeding mechanism which outputs via metering panel, uses patented feeding valve, with powder evenly output, having higher precision compared with the conveying modes of scraper type, screw and vibration, etc. 2.Adopting small-flow nitrogen or argon gas as feeding gas, which, together with powder that arrives at powder outlet with rotation of feeding panel on the bottom, enters the spray gun, to save more gas than traditional mesohigh powder feeder. 3.Compared with the traditional double barrel type powder feeder, the metering disc type powder feeder is more fine and the powder particle size range is wider. 4.Metering panel feeder is finer than traditional dual-barrel feeder and scope of powder particle size is wider. The internationally ultromodern inclined structure is adopted to facilitate cleaning powder by overturning the barrel to pour out powder using 3 seconds. |

|