In order to respond to the national environmental protection requirements, the noise and dust produced in the process of thermal spraying are eliminated. Therefore, noise control, ventilation and dust removal are indispensable parts of the whole thermal spraying process.

In order to respond to the national environmental protection requirements, the noise and dust produced in the process of thermal spraying are eliminated. Therefore, noise control, ventilation and dust removal are indispensable parts of the whole thermal spraying process.

Our company for the United States, Germany, Switzerland, domestic and other enterprises of thermal spraying main equipment supporting noise control, ventilation dust removal, automatic mechanical equipment, technology has gained a lot of experience accumulation and progress, is the domestic thermal spraying supporting the largest number of suppliers.

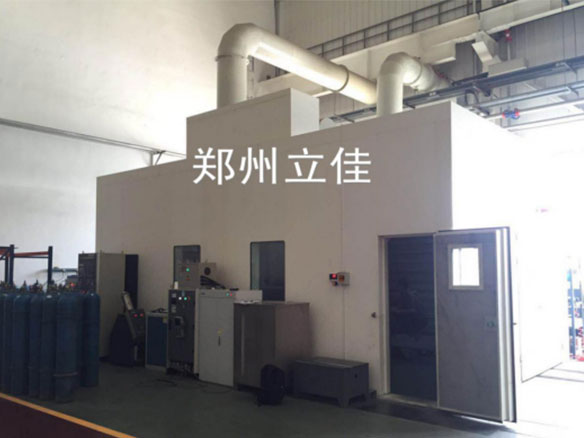

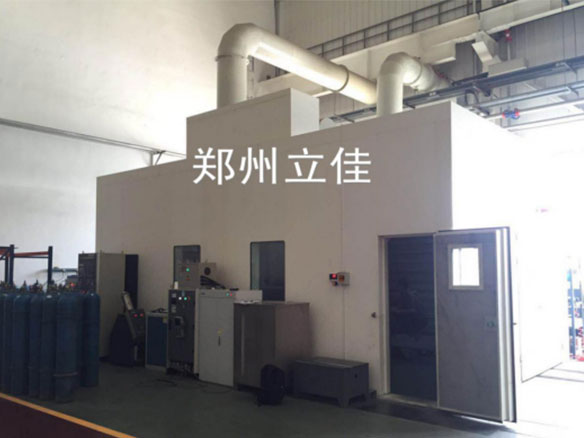

Set up spray sound insulation room. According to the principle of acoustics, the noise generated by spraying is controlled in the room, and the staff outside the room is prevented from being injured by noise pollution and nervous system. After the establishment of sound insulation room, the noise emission in the operation area shall be lower than the "Hygienic Standard for Noise in Industrial Enterprises" stipulated by the state.

Sound insulation room by four Angle steel columns, wall panel, roof, up and down trough, Angle, H type aluminum alloy, such as pieces of gap seal is special, not only ensure room sound insulation quantity and overall stiffness, and especially pay attention to outward appearance is beautiful and thoughtful detail processing, each project completed by the unanimous praise by users at home and abroad and praise.

The structure of the board group is as follows: the outer wall is white color coated board of 1.0mm thick, the damping layer is filled in, the asbestos board, 120g/m3 high-soluble reabsorbing cotton, waterproof and dust-proof sound permeating film, and the inner wall is metal porous sound absorbing board (punch rate of 25%). The sound insulation board is made of welded steel frame for strength support, and then pressed into shape. The sound insulation board is flat and smooth inside and outside, and the surface is bright and beautiful.

The standard width of sound insulation board is 970mm and the thickness is 100mm. The length can be determined by the height required by the room. The sound insulation board was tested by the State Key Laboratory of Acoustics of Shanghai Tongji University - the only nationally recognized noise Test data Center (no gypsum board was put in the tested sample), and the air sound insulation volume is 42dB (A) in the sound frequency range of 125-4000Hz. At present, the sound insulation volume of the sound insulation board after adding gypsum board is larger. The sound insulation board is assembled by the specially thickened aluminum alloy H profile, and the cement plug seam is used to prevent the sound leakage of the gap.

During the installation process often encounter the situation of existing cement the ground not level off, a direct impact on the door opening and closing, the owner is also difficult to guarantee the smoothness of the ground, and general workpiece in and out of the door is not allowed to sets the threshold, under given conditions, as well as guarantee the sealing of the week along the door and corresponding cement floor to ensure the flexible door switch without roughness. Therefore, we design the sound insulation door for the workpiece in and out as an automatic lifting form. When the door is opened to 90°, the sound insulation door is automatically lifted up by about 20mm. When the door is reset, the floor is specially swept and compacting under the door to ensure that the noise will not leak out from the gap under the door.

An observation window is provided on the sound insulation wall board and the sound insulation door. The observation window is made of transparent tempered glass, and the outside is covered with film. The number of observation Windows on the sound insulation board shall be specified by the owner. Observation window specification: 700*1000 (H) mm, three-layer tempered glass structure; The size of the observation window on the sound insulation door is 390*490 (H) mm, and its sound insulation is basically equivalent to the wall panel;

In order to meet the needs of indoor dust extraction and air absorption, the spraying room is equipped with inlet air muffler and exhaust air muffler to keep the balance of indoor negative pressure. Air flow through the muffler at the same time, indoor noise is absorbed by the muffler. Prevent noise from spreading outward through the air inlet.

Interior dimensions: 10m x 5m x 4.5m (l, W and H)

Wall thickness: 160mm

Appearance treatment: plastic spray

Observation window structure: three layer sealing structure

Inlet and outlet structure: expansion flow muffler structure

Noise reduction requirements: one meter away from the outer wall to 75 decibels

In order to collect and purify the free dust and disperse the spraying heat rapidly, a ventilation and dust removal system is set up in the spraying room.

According to the volume of sound insulation room, according to the number of air change 120 ~ 180 times /h to calculate and determine the air volume, the practical proof that the ventilation volume is the best.

With reference to the American design and our experience in ventilation and dust removal of hundreds of similar sound insulation rooms, it is recommended to use longitudinal air flow through the whole room, and set the air inlet on the roof and the arc uniform flow distribution network to eliminate the concentration of air intake and the dead Angle of ventilation, so that the air flow into the room evenly.

The design is of adjustable blade type, which can adjust the blade opening size to meet the needs of local flow rate and flow distribution. For example: in order to ensure the maximum cleanliness of the workpiece surface and rapid cooling and need to increase the flow rate of the workpiece range, the size of the opening of the blade can be adjusted to achieve the purpose;

The steel plate is rolled into the cylinder, supplemented by the color anticorrosion specified by the user. The pipe diameter is generally calculated according to the flow rate of 12 ~ 18m/s. The length and elbow of the pipe are determined according to local conditions and the equipment layout on site.